- All Categories

- EDUCATION

Summary Update: An updated version of this file, with a bigger variety and more accurate tooth profiles, is available here: http://www.thingiverse.com/thing:16627 One of the things I've been trying to do is print a pulley with a captive nyloc nut. However, the pulleys in PrusaJr's and Greg Frost's github pages, and the ones on thingiverse, all have some problems. Mostly it's that they are not parametric, or not openscad, or just stl, or rely on other files (Prusa's and Greg's) for some reason. So, as a way to get into learning OpenSCAD, I took Giles Bathgate's openscad copy http://www.thingiverse.com/thing:3104 of nophead's original http://www.thingiverse.com/thing:2079 , and the latest one from Prusa's githubhttps://github.com/prusajr/PrusaMendel mashed them up and tweaked extensively with the following:

- fully parametric, allows any size of pulley base, length of pulley teeth, number of teeth (see note below), number of captive nuts, size of captive nuts and a few other things besides (constants are at the beginning, currently, rather than using configuration.scad)

-

new parameters for:

- nut trap shape: allows hex or square nuts to be accommodated

- nut depth: can be edited for different nut types ie nyloc

- pulley base height: can be set to 0 for no pulley base

- pulley base diameter

- pulley teeth height

- number of captive nuts

- angle between captive nuts

- changing motor shaft size doesn't change the shaft cylinder outer dimension (weird mistake?)

- nut trap now parametised with nut size, and is consistent with opening (sides are smooth)

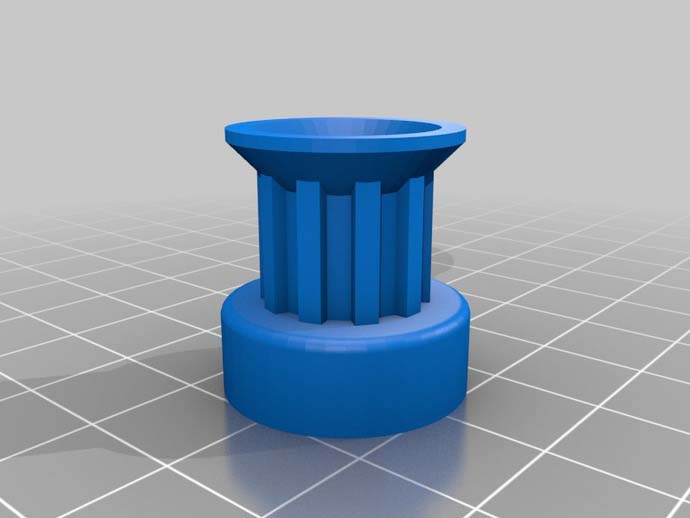

- can have a belt retainer on the open end of the pulley, made with a 45º ramp, to keep wandering belts on the pulley (not tested, can be turned off)

- grub screw hole altered for better printing

- no other file/library dependencies (I thought this was useful as this part often get reprinted on its own)

Update

- parameters for different tooth shape (T5 and XL specified)

- option for T5 or XL pulleys; amend tooth profile parameters and uncomment relevant part for correct tooth spacing

- space between shaft and captive nut is adjustable (triffid_hunter)

- belt retainer height is adjustable (triffid_hunter)

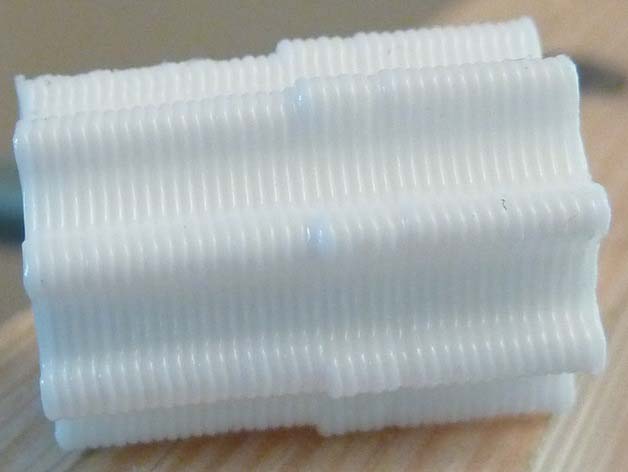

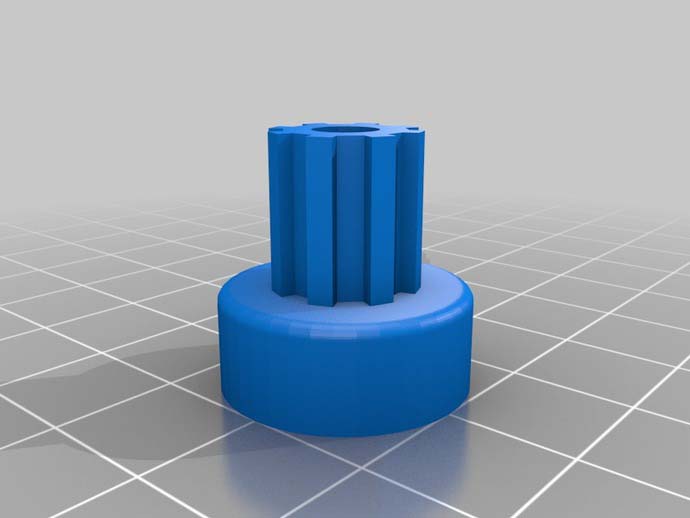

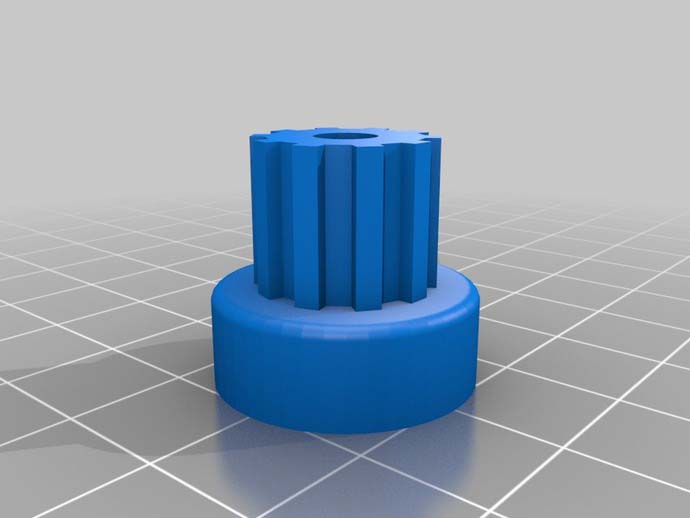

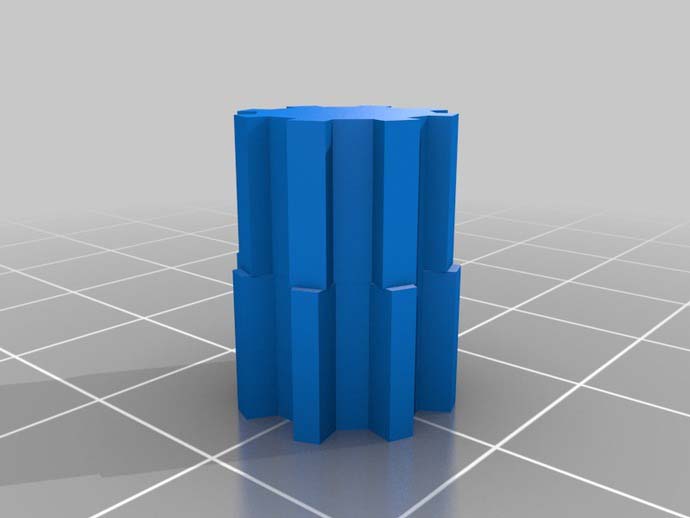

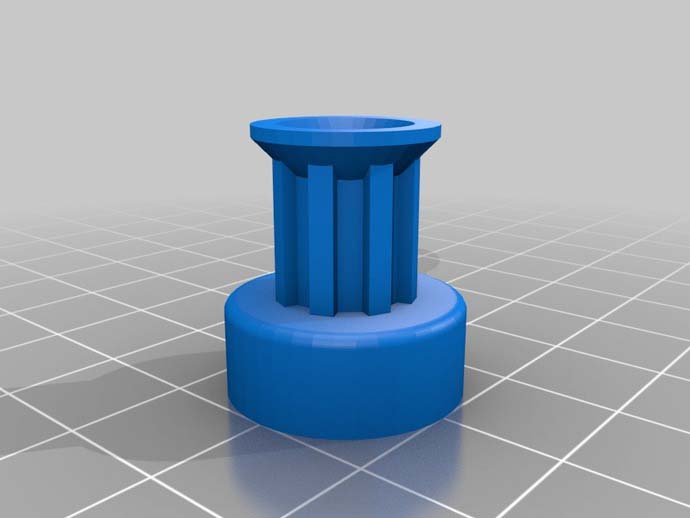

The scad files can be used to create a wide variety of pulleys and toothed idler sprockets, I've made a few different STLs to show, but in the end it's far better to download the scad file and make your own. Description of included three scad files: "pulley-T5-8_old_tooth.scad": does NOT have parametric number of teeth, it is fixed at 8 teeth. Everything else is still parametric. The teeth are the same size and spacing as the Prusa/Giles Bathgate/nophead version, which has generally proven reliable. "pulley-T5-N_old_tooth.scad": yu can specify how many teeth you want, however choosing 8 teeth creates a pulley that is slightly smaller (about 0.7mm) in diameter than the Prusa version. The tooth profile is still the same as the original tooth profile from the nophead version. "pulley-T5-XL-N_tooth.scad": is fully parametric, and uses a tooth profile that is defined by parameters, which allows for T5 or XL shaped-teeth. The tooth shape is subtracted from the pulley, unlike the original version, which is additive. I have included a couple of files for comparison, called "T5-tooth-comparison" scad and stl. The basic difference is that the original version has longer tooth spurs, but the angle of the tooth ramp is incorrect. You can adjust .scad file for deeper teeth, but if there is too much clearance you will get lash from the pulley. The attached STL files are generally sized with a small amount of tolerance, rather than being exact fit. "rtnr" means the pulley has a belt retainer on the end. All pulleys have a 3mm hole for an M3 grub screw, and a slot for a M3 nyloc captive nut. The wall outside of the nyloc nut might be a bit thin for a lot of pressure on the grub screw on the 8-tooth versions. Regarding tooth spacing: the relationship between the outside diameter of the pulley teeth and the number of teeth is not linear. I took the data for pulley teeth outside diameter fromhttp://www.cmtco.com/catalog/tp_mt.html#T5 andhttp://www.sdp-si.com/D265/HTML/D265T016.html put it in Excel and graphed the difference of pulley OD over number of teeth. After a few attempts at manually extrapolating the formula from the curve, I used the trial version of CurveExpert Basic from http://www.curveexpert.net/download/which quickly deduced a formula. This is all shown in the attached excel file. I slightly simplified the formula, added it to the scad file, adjusted the tooth placement and it seems to generate accurately sized pulleys. But the size of the 8-tooth pulley is extrapolated from the end of the curve, and I have nothing to check its diameter is accurate, as 8-tooth pulleys aren't commercially available as it bends T5 belting beyond it's specification. I did the same for XL belt. I can add more variations if there is any interest, eg T2.5, T10, MXL, 40DP, L. HTD and GT2 belts have rounded teeth, so will require a different method of creating the tooth profile. Any observations, comments and/or suggestion for additions or further improvement gratefully received.

Instructions

- Download the OpenSCAD files

- Play with the parameters until you have the perfect pulley

- Render and export as an STL.

- Convert to gcode, print.

Printing details not available.